Roar Solutions for Dummies

Roar Solutions for Dummies

Blog Article

The 10-Second Trick For Roar Solutions

Table of ContentsWhat Does Roar Solutions Do?The 4-Minute Rule for Roar SolutionsExamine This Report on Roar Solutions

In order to safeguard installations from a possible surge a method of evaluating and classifying a possibly hazardous area is required. The function of this is to make certain the proper choice and setup of equipment to eventually avoid an explosion and to make certain safety and security of life.

(https://www.figma.com/design/4A7baTVvle9Yit65rIBitI/Untitled?node-id=0-1&t=PKjLsk7ODuPV6hjT-1)

No tools must be installed where the surface area temperature of the tools is more than the ignition temperature of the provided hazard. Below are some typical dirt harmful and their minimal ignition temperature level. Coal Dirt 380C 225C Polythene 420C (thaws) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dirt 510C 300C Phenolic Material 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Residue 810C 570C The possibility of the danger existing in a concentration high enough to trigger an ignition will vary from area to location.

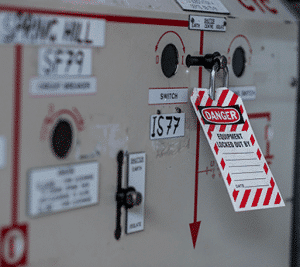

Dangerous location electric equipment maybe developed for usage in greater ambient temperatures. Field Fixing By Authorised Employee: Complex testing might not be required nevertheless specific procedures might require to be adhered to in order for the equipment to maintain its 3rd celebration ranking. Each piece of tools with an unsafe score should be assessed separately.

The smart Trick of Roar Solutions That Nobody is Talking About

The tools register is an extensive database of equipment documents that includes a minimum collection of areas to determine each item's area, technological specifications, Ex category, age, and environmental data. The ratio of Comprehensive to Close inspections will certainly be determined by the Equipment Risk, which is assessed based on ignition danger (the probability Check Out Your URL of a resource of ignition versus the likelihood of a flammable environment )and the hazardous location category

( Zone 0, 1, or 2). Executing a robust Risk-Based Assessment( RBI )method is crucial for ensuring conformity and security in managing Electric Devices in Hazardous Areas( EEHA).

An Unbiased View of Roar Solutions

In terms of eruptive danger, a hazardous location is an environment in which an explosive ambience exists (or may be anticipated to be existing) in amounts that need special precautions for the construction, installation and usage of devices. eeha courses. In this article we discover the difficulties faced in the work environment, the risk control procedures, and the required proficiencies to function securely

These substances can, in particular conditions, develop explosive environments and these can have major and awful consequences. Many of us are acquainted with the fire triangle remove any type of one of the three components and the fire can not occur, but what does this mean in the context of unsafe areas?

In most circumstances, we can do little about the levels of oxygen in the air, but we can have considerable impact on resources of ignition, for instance electrical equipment. Harmful locations are documented on the dangerous area category drawing and are recognized on-site by the triangular "EX LOVER" indicator. Here, amongst other vital information, zones are split into three types relying on the danger, the likelihood and period that an eruptive atmosphere will exist; Area 0 or 20 is considered the most harmful and Area 2 or 22 is regarded the least.

Report this page